You’ve probably noticed that we mention the food-safe properties of some filaments. And it’s true, there are several materials that can be considered food-safe, or food-grade to be specific (only certain manufacturers have proper certification), but it’s still necessary to coat the surface to make it truly safe for direct food contact. Let’s see why the surface coating is so important, how to add it properly, and what to avoid during the whole process.

Important regulations

First, let’s talk about regulations: In Europe, there is regulation no. 10/2011 that summarizes safe and unsafe materials. In the USA this issue is covered by the FDA CFR 21 document. While there are many materials that are classified as food-grade, there are only a handful of manufacturers who have completed the rigorous and costly certification process. In general, certified materials are more expensive. If you need to make food-grade parts for your business, you will be interested mostly in materials with a valid certification.

Food-safe filaments

Let’s take a look at materials that are (not) suitable for direct contact with food. As we mentioned above, you can buy materials with food-grade certification (PLA by Filaments.ca for example). But some filaments should be safe even without any certification, for example, PLA, PETG, or PP. On the other hand, some materials are rather unsafe and shouldn’t be used for direct food contact – for example, most ABS or ASA filaments. Unfortunately, it gets more complicated, because we need to take into account the pigments that are used to produce various materials. Even potentially safe filaments might contain unsafe pigments that might be dangerous when in direct contact with food. Therefore it’s good to ask a manufacturer about additives used, or use natural filament with no added coloring. Most of our PLA and PETG Prusaments (excluding PLA Army Green)* contain inorganic non-migratory pigments that should be safe, but keep in mind that we didn’t acquire any certification. If you print food-grade objects with our filaments, you should do it only for personal use, not for sale.

*Our coloring manufacturer confirmed that these colors should be safe for food contact: PLA Galaxy Black, PLA Galaxy Silver, PLA Azure Blue, PLA Lipstick Red, PLA Galaxy Purple, PLA Jet Black, PLA Prusa Orange, PLA Pineapple yellow, PLA Royal Blue, PLA Ms. Pink, PLA Opal Green, PLA Pearl mouse, PETG Jet Black, PETG Prusa Orange, PETG Signal White, PETG Carmine Red, PETG Yellow Gold, PETG Urban Grey, PETG Ultramarine Blue, PETG Galaxy Black, PETG Pistachio Green, and PETG Terracotta Light.

3D printer preparation

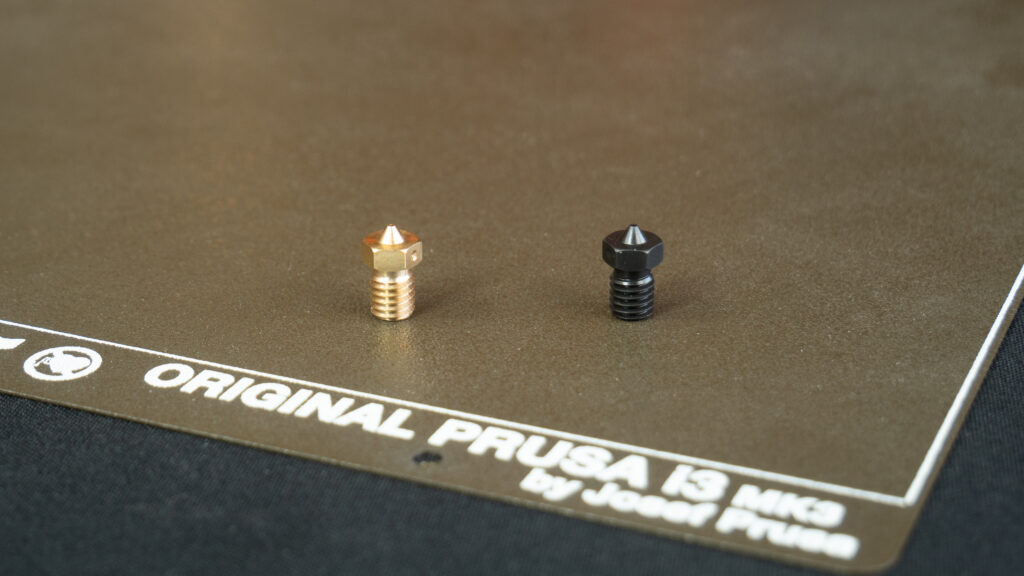

Once you select the right filament job, it’s time to prepare the printer. First, you need to keep it as clean as possible (outside and inside). You should try cold pull if you aren’t sure whether the extruder is clean enough. Then you should consider changing the brass nozzle for a stainless steel one: Brass nozzles (and even our hardened steel nozzles) might cause a health risk due to lead present in the alloy. Few sources also claim that it’s not wise to print with an extruder containing PTFE tube, due to Teflon toxicity at high temperatures. However, it releases only a small amount of toxic particles with temperatures exceeding 240°C and significant amounts with temperatures over 260°C. PTFE, therefore, poses no real danger if you print with PLA or PETG. If you are still not sure, try to use a special extruder without a PTFE tube.

No print is food-safe without surface coating

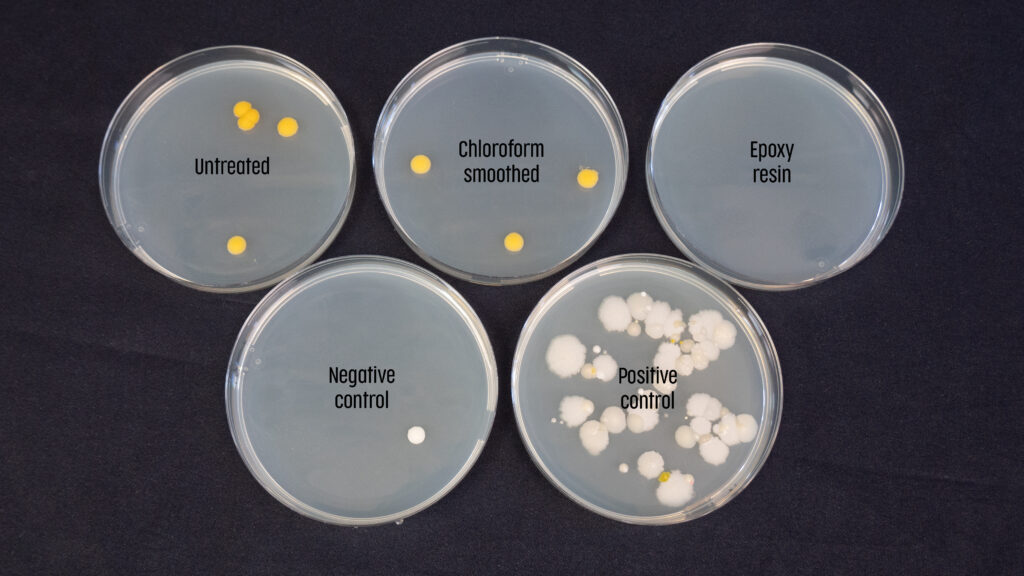

Choosing the right filament and using a well-maintained printer is just the beginning. The print itself will never be food-grade for one simple reason – FFF 3D printing produces objects containing gaps between the layers. These gaps can become the breeding ground for the growth of bacteria and fungi, which can cause an illness. Of course, you can reduce the number of gaps by decreasing the layer height and adding a 100% infill, but the results will never be good enough. You should make the surface as smooth as possible. Unfortunately, this cannot be done properly with chemical smoothing: ASA and ABS are mostly unsafe materials and PLA/PETG can be smoothed only with dangerous chemicals. Plus, the result is never perfect – there are lots of tiny bubbles that can contain bacteria. We have prepared a simple test to show you the real danger of untreated models: We printed three PLA cups where the first remained untreated, the second was smoothed with chloroform and the third was coated with epoxy resin. Then we simulated regular usage by pouring milk inside every two days and washing it with warm water after several minutes or hours. After 14 days of testing, we performed a smear test of the surface and cultivated present bacteria on LB agar plates for 7 days. As you can see, untreated print got the worst results (largest colonies) and epoxy resin the best results (no colonies).

This method was inspired by a test made by University Novi Sad, mentioned in My Tech Fun video.

Negative control was made by cultivating smear test from freshly printed PLA cup (no milk was involved), positive control was a smear test of sink surface. Bacterial colony present in negative control may have grown due to contamination from air or other sources.

Safety first

It’s obvious that the surface must be coated to become consistent, smooth, and easily washable. This can be achieved with clear and food-grade epoxy resins. But be aware that there are more rules to follow! Failure to follow these rules might lead to contaminating or even poisoning the food.

Resins are usually toxic materials that are not appropriate for food contact and all epoxy resins are toxic when in liquid form! Similar to filaments, many epoxy resins should be food-safe after curing. But most of them aren’t certified and suitable for commercial use. It’s recommended to use the one with proper certification, even though it might cost you more. For example, we have used Efkoresin Art UV which is certified according to EU regulations 10/2011.

Once again we would caution you regarding the use of uncertified resins! Especially if you do 3D printing for a living and sell food-grade products to your customers!

The last thing to keep in mind is the toxicity of uncured resins (this even applies to those with certification). If the resin is not cured enough, it might become toxic! You should follow the manufacturer’s recommendations because an incorrect ratio of resin and hardener might be toxic. And once again, we must emphasize the fact that liquid resins are toxic. Please, use gloves and a respirator (spray paint half-mask) to prevent allergies and other health issues.

If you follow the rules mentioned above, you can be sure that your 3D printed kitchenware will be truly food-grade. But be aware that resin-coated 3D prints will have some limitations compared to regular dishes. We’re talking about wear and heat resistance: This process is not suitable for producing chopping boards (prone to scratching) or for products which will be exposed to heat – such as hot soups, microwave ovens, or dishwashing machines (read more about material deformation in our annealing article).

Is SLA technology food-safe?

Some of you might come up with questions about using SLA resins either for printing the dishes or food-grade coating. In short: It is not a good idea. Most SLA resins are toxic both in cured and liquid forms. Resins are also very prone to wear (forming a fine powder on the surface). There are various dental or low odor resins but these are made for special purposes and they are very expensive. If you wish to make 3D printed dishes, it’s better to stick to FFF printers and certified epoxy resins.

We hope that our article proved that printing food-grade dishes is not as simple as printing normal models. You need to follow many detailed rules as mentioned above to ensure that your model does not become toxic or full of pathogens. This is especially important if you run a 3D printing business for a living. Either way, surface food-grade coating surely brings new horizons to 3D printing.

Note that the same methods can be used to make 3D prints for completely different applications, but with similar requirements. For instance, you can imagine some aquarium accessories, where you need to coat the surface to prevent the buildup of algae.

Try to make nice food-grade print yourselves and show us the results. But don’t forget: Safety first! And as always – happy printing!

I’ve heard this argument about the layer lines trapping microbes at lot and the video you link seems to substantiate the fact that they are harder to clean but I still wonder how bad that is. Below are a few questions I have.

1) People happily use wooden kitchen utensils and cutting boards all the time and there’s no outcry to throw those away and stop using them. They certainly have a lot of pores were microbes can hide.

2) Your experiment and the one in the video just proves the things you tested aren’t sterile. Not sterile things can be food safe. I don’t autoclave everything before using it in the kitchen and I suspect you don’t either.

You also don’t have a standard for what constitutes a food safe item like you do for a food safe material.

One crude test you could do is compare your microbe tests to tests on other kitchen items considered safe. How about a ceramic mug, a glass cup, a new and old plastic cup? a wooden spoon/bowl?

3) As side not “colony size” is not a measure of how many microbes were in your original sample. Each colony represents a single colony forming unit (CFU) in the sample taken. A CFU is generally a single cell though depending on the microbe it can be a floc too. Between three and five CFUs is quite a small number. I bet if you plated a ml of tap water you’d get a lot more than that.

Also, try plating samples of some of the fresh prepared food form the deli (salads, salsas, etc). I’ve done it before on a lark and always found plenty of microbes. Maybe food isn’t food safe either.

James is asking the real questions. Not being classified as food-safe doesn’t necessarily mean it’s not safe.

Pretty sure humans survived to this point just fine using porous and toxic materials.

No human born before 1900 has survived 🙂 The idea that the human race is still here therefore porous materials are safe makes no sense. Average life expectancy in 1900 was 31-32 years. Now it’s 72+. A lot of that is due to hygiene, sanitation and a proper understanding of micro-organisms.

I have no idea how dangerous it is to use raw 3D-printed bowls and neither do you 🙂 but I feel like the choice between 0 bacterial cultures and 3 is a no-brainer. If that’s what’s going on after just 2 weeks, that’s going to get pretty nasty.

+1 good questions!

Regarding 1.

The porous nature of hardwood is what makes it safe. It’s porous enough to absorb microbes and moisture, but dense enough to trap and kill them when it dries (rather than letting the microbes have room to grow).

It’s why a hand washed wooden cutting board smells inoffensive, while well rinsed and wrung

(Oops I butter fingered enter on my phone. Let’s continue where I left off.)

…while a well-rinsed and wrung sponge smells like rotting death after a day.

One last thing. The concern about microbes isn’t always really about toxicity and infection. Microbes can be harmless to humans, but still excrete awful odors that can ruin food (you taste with your nose too!).

Hello, xXDankLordXx explained the first point very well (thank you).

2) and 3) Yes, it surely shows that it’s not sterile. This isn’t a proper scientific experiment but more likely a visualisation of the problem we’re talking about. We don’t have a well-equipped laboratory and we aren’t microbiologists. 🙂 But the experiment made by Igor Gáspár (attached video by my tech fun) has better potential and hopefully we’ll see an article about it soon. Actually, I would like to learn about this topic something myself but there aren’t many articles about food-safe 3D printing. Long story short: This is work for microbiologists to try. We simply want to be sure that people don’t become sick and that can surely be done better with using (and cleaning) smoother surface rather than rough and porous one.

RE: “1) People happily use wooden kitchen utensils and cutting boards all the time and there’s no outcry to throw those away and stop using them. They certainly have a lot of pores were microbes can hide.”

as a chef, there’s a reason wood is avoided. Though you and others hit on important points. Not FDA approved isn’t the same as not safe for consumption. Neither is not perfectly sterile situations. But again, there’s a reason why certain things are avoided like wood beyond the degradation exposed to the conditions of a kitchen on a habitual basis.

100% with you Chris, and people nowadays seem to think that being able to grow 3 bacteria from a surface is a disaster while ignoring the fact that their bodies are absolutely riddled with billions of them. The truth is a lot more complicated, but … (medically trained and passionate about 3D printing) … I fundamentally feel that your argument is good and the drive towards impermeable surfaces somewhat excessive, especially if it adds a whole load of new chemicals and polymers to the process. You only live once, and in my humble (but medically well-educated) opinion you don't want to live forever either, so go wild and add those 3 cultures to your mouth along with the billions already there / on your fingers and food.

Great article.

It would be worth discussing annealing or salt remelting of 3d printed parts. I realize this is hard to do, but for personal use food contact items, it’s a viable option.

I expect the annealing methods would reduce porosity, even though they would have surface roughness. Has Prusa collected any data on annealing methods?

Thank you for the tip. We haven’t tried annealing for food grade purposes but it is surely worth a try.

This article needs a big fat disclaimer about the qualifications of the author.

You should also consider contamination from lubricants, other non-safe filaments that have been in the printer before, the material and lubricants on the extruder gear, etc. To be food safe you can’t just use food safe material, your whole process has to be food safe.

Thank you. I wrote that the printer must be as clean as possible (outside and inside) but next time I’ll try to be more specific.

Since epoxy can still be dangerous if not used properly, could covering the part in a thin layer of silicone be a better option? As far as I know it’s generally food safe.