The Original Prusa SL1 was our first foray into the world of SLA printers. We wanted to build a solid, sturdy and robust 3D printer that would produce consistent, high-quality 3D prints. Based on the general feedback and reviews, we did many things right. The SL1 found its way not just into hobbyists’ workshops but into various industries as well. As usual, we started collecting feedback and thinking about improving the machine even further – one of the areas we wanted to focus on was its print speed.

Today, I’m happy to announce that the improved version of the SL1 is finally here! With a brand new high-resolution monochrome LCD, larger print platform, and all cumulative updates from the entire lifespan of the SL1, the new SL1S SPEED is a lightning-fast machine that produces amazingly detailed 3D prints. Check out the video below to get a comprehensive overview of the new features:

Original Prusa SL1S SPEED is here!

While SPEED is the main word here, it’s not at the expense of quality. On the contrary, the SL1S Speed offers even better print quality than the original SL1. We replaced nearly everything under the hood, so while the SL1S may look the same from the outside, it’s a very different 3D printer.

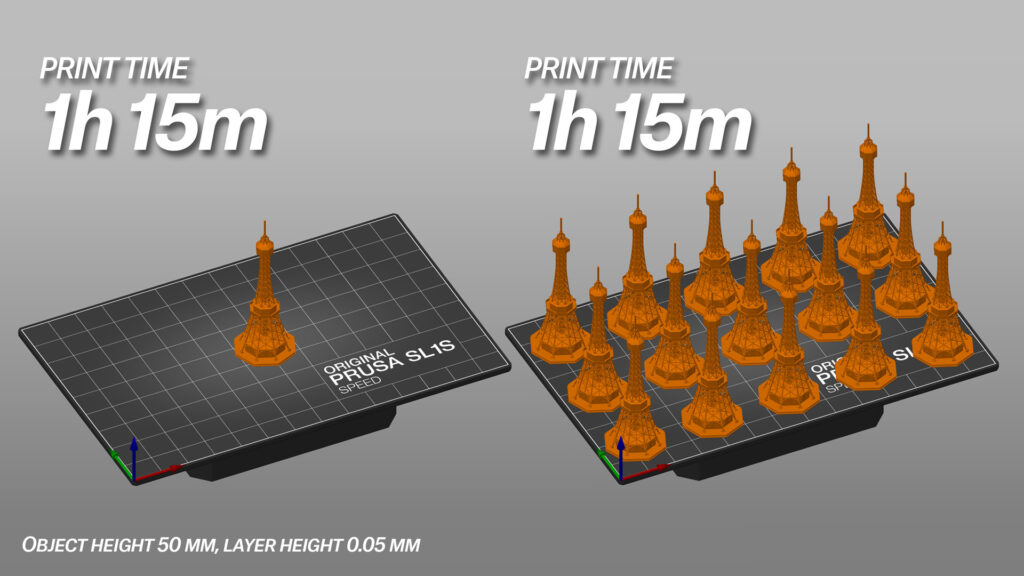

We touched up nearly all of the SL1’s main features. The print platform is 25% larger to match the new 5.96’’ LCD screen, and it now has a tapered top. The new print volume is 127×80×150 mm, and the SL1S can now cure a single layer in just 1.4 seconds (low layer height, transparent resin) and can reach up to 80 mm/hr using 0.1mm layer height and transparent resin, which is especially perfect for quick prototyping.

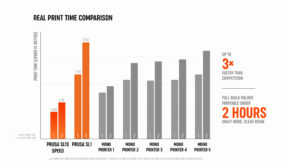

Standard tough 405nm resins can be cured in 1.6-2.5 seconds, depending on the object size, resin manufacturer and layer height. Advanced materials that would otherwise require 20+ seconds per layer can be cured in only 3-4 seconds, a massive improvement. However, measuring an SLA 3D printer speed is not just about the exposure times – a significant amount of time is dedicated to the movement of the platform. And this is why made the tilt and platform movement nearly three times faster. We also redesigned the tank, increased the total power of the UV LED panel, improved the firmware… pretty much no stone was left unturned. Using the draft quality option, you can now print a 150 mm tall object in two hours!

It all started with our intention to use a monochrome LCD screen instead of the standard RGB display. A monochrome LCD is excellent for SLA 3D printers because it offers vastly improved UV light transmission, which means shorter exposure times, better print quality, and faster printing. Plus, the SL1’s mono LCD has four times the lifespan of a regular RGB display – more than 2000 hours. However, it’s not as simple as replacing one type of screen with another. I’ll dig into the details in a minute.

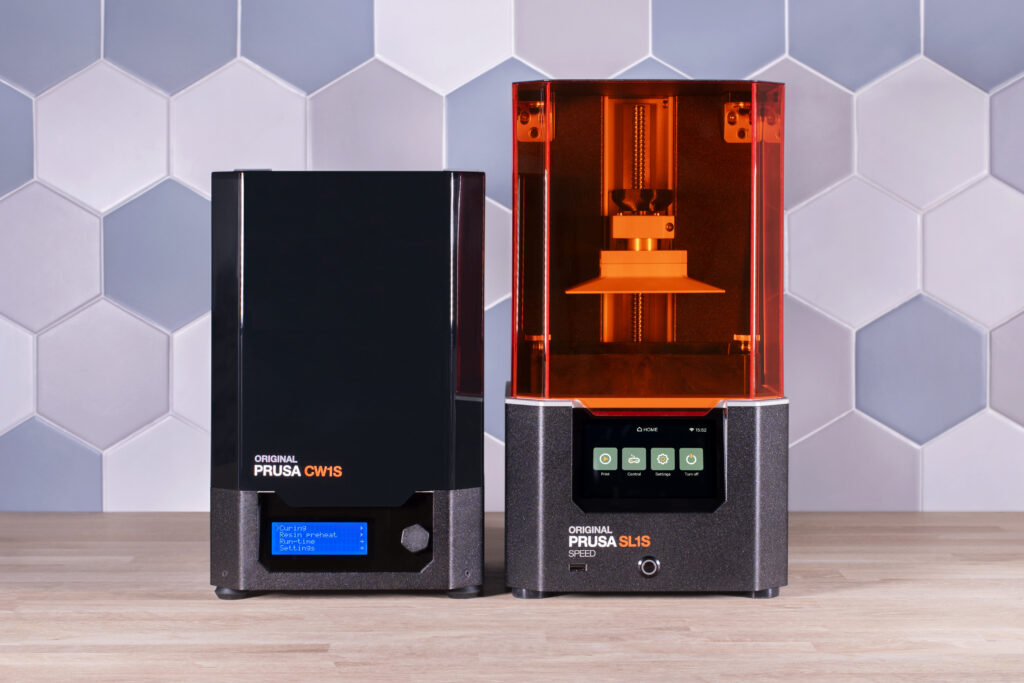

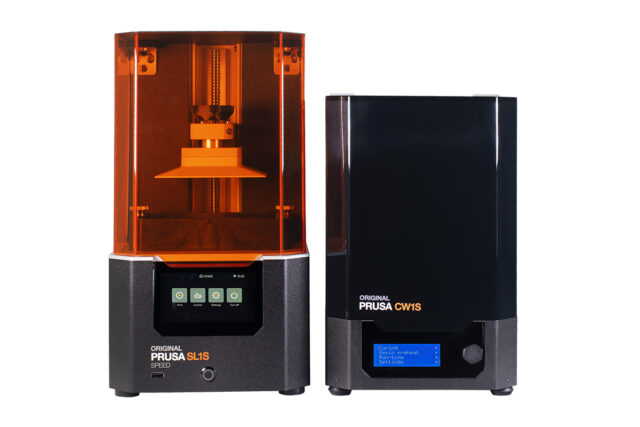

If you are currently waiting for your SL1 and the package has not yet shipped, rest assured you will receive the upgraded SL1S at no additional cost. The Original Prusa SL1S Speed and the updated Curing and Washing Machine (CW1S) are already on our e-shop, you can get the SL1->SL1S upgrade kit here, and a discounted bundle is also available. Shipping starts in late June / early July 2021.

Increasing the speed

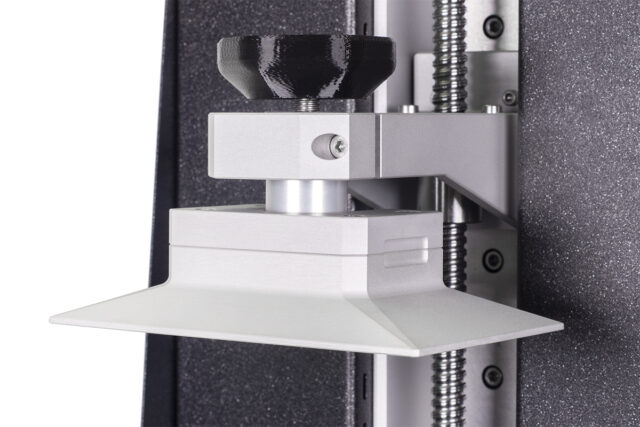

To make the monochrome LCD work, we had to go back to the drawing board and completely redesign the printer’s optical and UV LED systems. The original SL1 uses a V-shaped reflector, which worked well with the RGB screen. However, the new monochrome LCD has a different raster, which requires an entirely new solution – you can see it in the photo below.

While we were at it, we also replaced the old UV LED panel with a brand new LED array, which is four times more powerful. Finding the optimal ratio between screen type, position, UV LED size, lens, and other elements was key. Granted, this all took us a while, but the results are very well worth it. Even with the standard 405nm resins (like Prusa Tough resins), you can get as low as 1.6 seconds of exposure per single layer easily, which means more than three times shorter exposure than the SL1. Smaller objects printed from transparent resins may reach as low as 1.4 seconds per layer.

This opens up a brand new field of possibilities – resins that would otherwise take 20-30 seconds to cure with uncertain results can now be exposed for 3-4 seconds, which is especially useful for industrial applications, ranging from automotive to medical. The SL1S can definitely do more than print miniatures – it can easily compete with 2-3 times more expensive machines. After all, the SL1 soon found its way to all sorts of industries – it is actively used in the Czech Institute of Experimental Medicine (IKEM) and in Skoda Auto Company. NEU3D Laboratories uses the SL1 for flexible bronchoscopy training. And there are many more.

|

|

The new Original Prusa SL1S SPEED uses the same tilt mechanism for highly reliable printing as the SL1. Once a layer is cured, the tank tilts downwards, the print platform rises, and, finally, the tank returns to its position. This has three significant benefits: first, the peeling forces are lower, eliminating the risk that the print would detach from the printing platform. Second, the tilting motion also stirs the resin and allows it to distribute evenly under the printing platform. And third, the process is up to 2-3 times faster compared to non-tilting machines. We pushed the mechanism even further with the SL1S: the tilting motion runs for 5 to 8 seconds on the SL1, however, we squeezed it down to mere 3 seconds in the SL1S. Our tilt-based system is a massive advantage here and it makes the entire process much faster than other SLA 3D printers.

All of this combined means that you’ll be able to produce a 150mm tall object in two hours when using increased layer height. This is great, e.g., for prototyping and testing because you’ll be able to print more in less time. The printer can, of course, operate in a wide range of layer heights, depending on your needs. The technology allows it to reach even 0.01 mm, which is, of course, not very beneficial for real-life scenarios. This is why we offer layer heights between 0.025 to 0.1 mm in our factory-tested print profiles, ranging from ultra detail to draft quality (which still looks much better than FFF/FDM 3D prints).

Improving the print quality

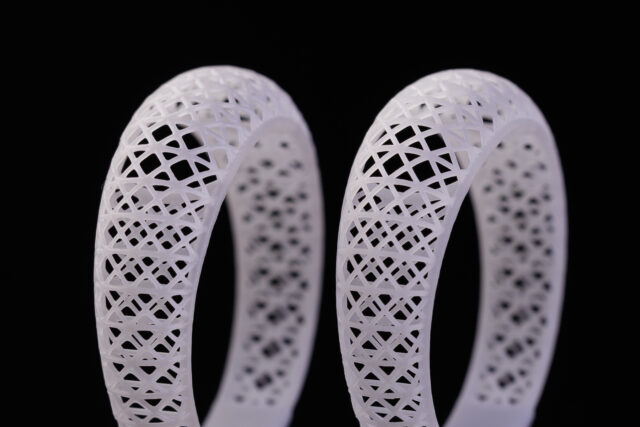

The new monochrome display and reworked optics bring another important feature: vastly improved print quality. While the physical resolution of the LCD screen is nearly identical (2560×1620p vs. the original 2560×1440p), the prints from the SL1S look even better.

How the UV light spreads through the optical system significantly affects the print quality, so it’s not just the physical resolution. We have improved how the UV light is directed through the display – and now, even the tiniest details are crisp and perfectly defined.

And because seeing is believing, the Sample Object package is available in our e-shop for you to check out. You’ll receive a package with sample objects printed on the SL1S so that you can inspect the quality with your own eyes. You can also find more high-resolution photos of prints from the SL1S on the product page.

Useful little upgrades

While the monochrome LCD, improved quality, shorter printing times and larger print platform are the main features of the SL1S, there are many other changes.

By popular demand, we’ve redesigned the print platform, so now it has angled top sides. The firmware development picks up where the latest firmware for the SL1 left off, which means the printer has intuitive controls, offers advanced functionality (network printing, print statistics and much more), and the initial setup is quick and convenient thanks to an assisted step-by-step wizard process. Just like with all our 3D printers, the SL1 received continued firmware updates during its lifespan, and the SL1S will be no exception. We’re planning to support both the SL1 and the SL1S with new firmware updates in the future.

Another part of the printer that received a nice touch-up is the resin tank. With the SL1, we were using a fully aluminum tank, which was quite expensive. The new tank from high-quality graphite-reinforced PA6 composite is available for 24.99 USD/EUR (VAT incl.), and it comes with a practical opaque lid, so the tanks are now stackable. Let’s say you have two favorite resins, so now you can keep them in two separate tanks and switch between them depending on your needs – the lid protects the resin from being cured by daylight. This means that you don’t have to pour resin back into the bottle every time you switch materials. Replacing the FEP film in the tank is easy and cheap – no expensive proprietary tanks!

We have also updated the Curing and Washing Machine, an amazingly useful accessory for any SLA 3D printer out there. The lengthy and messy process of washing, drying and curing the print can be reduced to mere minutes thanks to the CW1S. It’s an all-in-one device, so it can do all the necessary post-processing work. Plus, it can also preheat resins to optimal temperature. The CW1S features a reworked heating system. The removable rotating platform is now protected by a replaceable FEP film, making the maintenance even more effortless. You can easily upgrade the platform in your CW1 by downloading an STL, which we will publish in the upcoming days, and getting a FEP film from our e-shop (it will be available soon).

However, due to many external factors, such as higher costs of certain parts, issues with transportation, problems with the availability of specific components, we had no other option but to increase the price of the SL1S and discontinue the assembly kit option. It wasn’t an easy choice, but opting for lower-quality parts was out of the question – the SL1S still uses the same high-quality materials and extremely rigid frame with an easily accessible workspace.

Based on our internal statistics, the kit was far less popular than the assembled printer. The philosophy behind SLA 3D printers, in general, is slightly different than FFF/FDM 3D printers – there are far fewer mods and tinkering with SLA printers. Also, producing assembly kits for a machine with this level of precision is no small feat. However, rest assured that the SL1S is still Open Source!

Both machines along with the SL1S upgrade are available in our e-shop. And if you’re interested in buying both machines together, don’t forget to take advantage of the discounted bundle. Shipping starts in late June / early July 2021.

- Original Prusa SL1S SPEED for 1,999 USD / 1,979 EUR (VAT incl.)

- Original Prusa CW1S for 749 USD / 749 EUR (VAT incl.)

- Original Prusa SL1S SPEED bundle with CW1S for 2,599 USD / 2,549 EUR (VAT incl.)

- Original Prusa SL1S upgrade kit for 399 USD / 399 EUR (VAT incl.)

You can check out the complete feature list below. Of course, you’ll get our 24/7 tech support, knowledge base articles, useful guides and tutorials, plus a worldwide warranty. The SL1S is fully supported by our internally developed PrusaSlicer, which comes with tested print and resin profiles.

Happy printing!

| SL1 | SL1S | |

| SLA system | LCD and UV LED panel (MSLA) | LCD and UV LED panel (MSLA) |

| Display type | RGB with V-shaped reflector | Monochrome LCD with a high-performance lens system |

| LCD resolution | 5.5’’, 2560×1440p | 5.96’’, 2560×1620p |

| LCD lifespan / warranty | 500 hours | 2000 hours |

| Print area size | 120×68×150 mm | 127×80×150 mm |

| Layer exposure time | 6 – 8 seconds depending on material and layer height | 1.4 – 2.5 seconds depending on material and layer height |

| Tilt times | 5-8 seconds | 3 seconds |

| Supported layer heights | 0.025-0.1 mm | 0.025-0.1 mm |

| Minimal layer height | 0.01 mm | 0.01 mm |

| Supported materials | Standard UV sensitive liquid resin, 405nm | Standard UV sensitive liquid resin, 405nm, advanced materials supported |

| Connectivity | USB, Wi-Fi, LAN | USB, Wi-Fi, LAN |

Features:

- Highest quality UV LEDs – we select only the best and most consistently performing parts to ensure that all manufactured printers can deliver the same level of exposure. All SL1S 3D printers have factory-calibrated displays, which makes them easier to replace compared to the SL1, which required an additional calibration once a display was replaced.

- Quick-release platform – maintains calibration. No need to recalibrate the printer when the platform with the print is removed.

- Assisted Wizard for quick and easy setup and calibration

- Motorized tilting bed – prevents layer shifts, stirs the resin, enables faster printing, improves reliability

- Resin tank with non-proprietary FEP films – easy and cheap replacement, low running costs

- Silent operation with Trinamic drivers (auto-homing function)

- Advanced cooling system improves performance and extends the life of internal components

- Rear fan with a carbon filter to minimize odors around the printer

- Safety features: resin level sensor, safety vat under the tilt mechanism to protect the internal parts against minor resin spills

- Fully-featured network interface: control your printer through your web browser

Man, I was excited to be getting an SL1, and was fine with the specs as-is. Now finding out that I’m gonna be getting an SL1S instead? Hooooooboy, now I’m *really* stoked! I can’t wait to give it a shot, this sounds like rather a whole new ball game.

Lots of online system you can apply https://freerobuxnoverification.co and these are for who have interested in some kind of online information.

Marketing is a fast evolving field and one of the many future career trends for marketing interns is to pursue internships that focus on advertising or promotions in the field. If you choose to focus your future career expectations in the advertising or promotional industries – https://www.digitalconnectmag.com/4-future-career-trends-for-marketing-interns/ you will need to be prepared for both positions, the internships and the hiring processes that go along with them. One of the primary tasks of marketing interns will be working with a company to create marketing campaigns. This includes creating print ads, posters, business cards and other types of promotional material for businesses. They will then be responsible for implementing these efforts through various means, from word of mouth to networking and promotional events.

The SL1 had a resolution of 120mm/2560 = 47µm.

The SL1S resolution is listed with 127mm/2560 = 50µm.

Isn’t that a downgrade?

Good share! Thanks