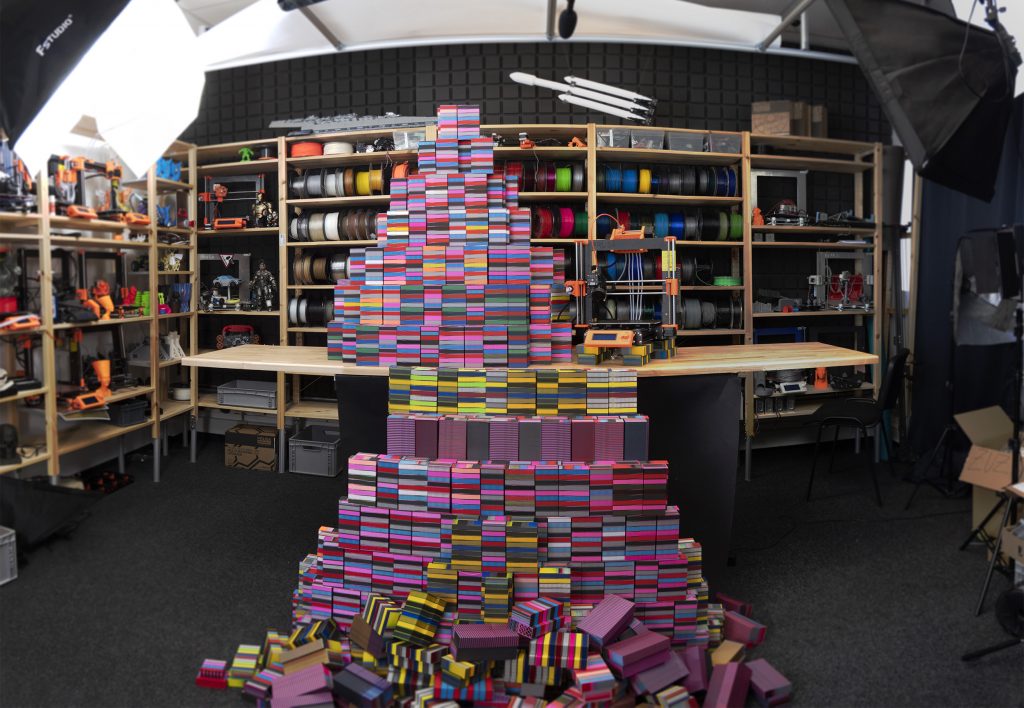

Hello everyone, it’s time for another update and this time it will be a pretty massive one. We have been growing as fast as ever, and we already reached the incredible milestone of 100,000 3D printers shipped! Just in January, we dispatched 14,000 orders (not all of them are printers). I would have never imagined that when I started. We are actually working on a short documentary how we got (literally) from a basement to this level, I am beyond excited to show you parts of the story you never saw and I’m pretty sure you will love it, too. 🙂 But you are probably already excited about the MK3S and MMU2S from the title, so let’s get to it.

Table of contents

- Original Prusa i3 MK3S / MK2.5S

- Original Prusa i3 MK3/MK2.5 MMU2S

- New firmware

- Textured sheets

- Original Prusa SL1

- Slic3r PE

- Prusament

Original Prusa i3 MK3S / MK2.5S

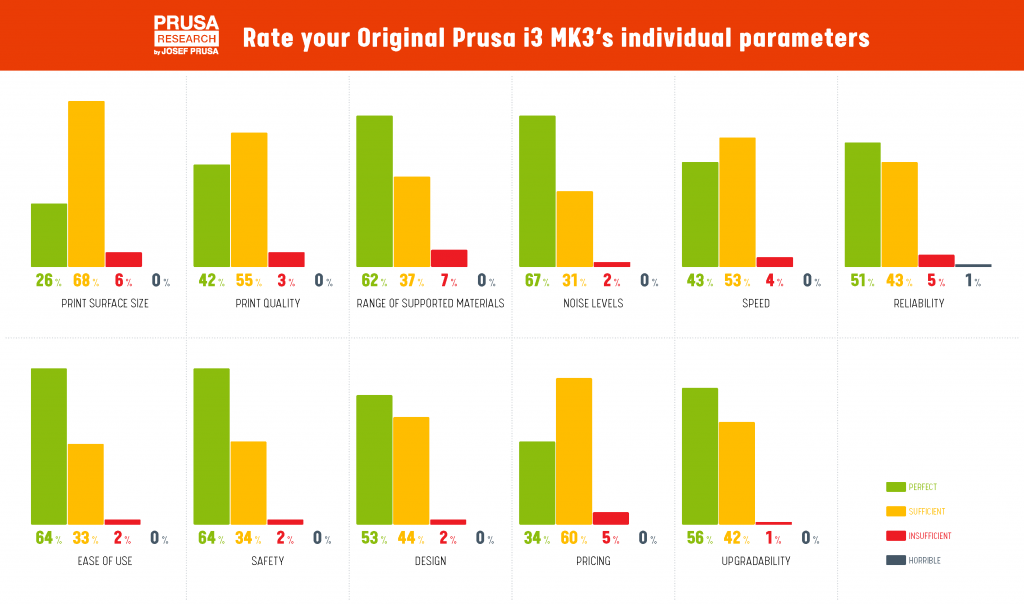

Some time ago we did a big survey about our products and it was immensely helpful. I want to thank everyone who participated. Constructive criticism is the best thing we can wish for and it helped us shape the updated products of MK3S and MMU2s.

Don’t get me wrong, the printers are awesome and your feedback from the survey proves that. We also won first, second and third place on latest MAKE: Magazine 3D printer shootout which is pretty epic. But we just can’t sit and not improve.

Results of our 3D printing survey regarding MK3 were very satisfying

With Original Prusa MK3S we are introducing a completely reworked extruder with a new filament sensor. The previous sensor didn’t work well with some specific filaments. We did hear the community that we should try a different approach so we decided to go back to the drawing board. Mechanical switch approach is an easy solution. However, we’ve been testing them a long time ago and it proved to be unreliable in the long term run. Trust me, it didn’t survive on our farm for long. Eventually, the hybrid of the two is the best solution. The new sensor is using the optical sensor which is triggered by a simple mechanical lever. This sensor doesn’t care about the optical properties of the filament (it can be completely invisible) and cannot die because of mechanical wear.

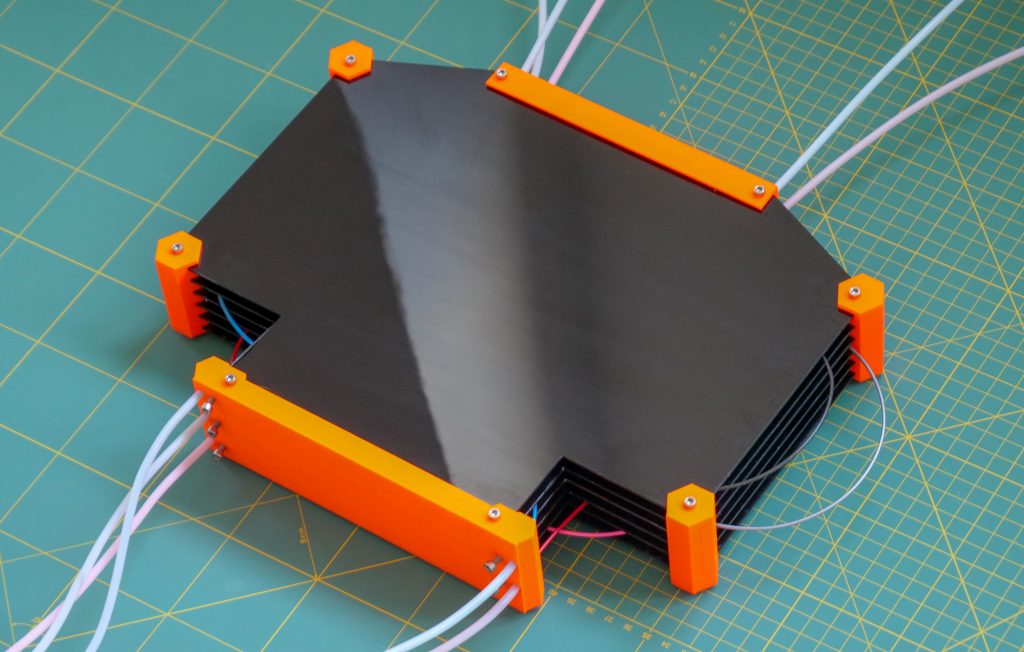

The mechanism of the re-worked filament sensor (the orange plastic part is black on production printers – this orange part is only for demonstration purposes)

When we were on it, we redesigned the whole extruder assembly. The feedback from the survey and our user groups indicated that it should be easier to service. So now you don’t have to take apart the whole extruder if you want to change the nozzle or PTFE tube (two spare ones are now being included BTW). As a bonus, the nozzle and the extruder motor is much closer to the X-axis, this means less resonance and better prints too – this is also thanks to improved cooling. Better Y-axis belt tensioning is just the icing on the cake.

And, of course, the MK3S includes all the cumulative upgrades from the entire life cycle of the MK3. Before the release, we have made several improvements – like using genuine Gates belts, we also replaced the spiral wraps with textile sleeves, created a new Einsy case, added an anti-rust coating on smooth PEI sheets (more info below) and, of course, there are dozens of firmware and plastic parts enhancements.

The best part is, that the new MK3S is shipping since Friday, 8th February. You can get it from our eshop at the same price as the MK3 – 749 USD or 769 EUR (VAT included). Lead time for a kit is currently only 2 weeks.

If your MK3 printer has been shipped in the last two weeks (from January 28th onwards)*, we will automatically send you the voucher for the upgrade for free during this week. You don’t need to contact our support team about that. These upgrades will have the printed parts printed by us.

*Update 13/02: Including all MK3 kits and upgrades and MK2.5 upgrades.

The regular price of the MK3S and MK2.5 upgrade kits are only 19.99 USD / EUR (vat incl.) when you print plastic parts by yourself and you can buy them right now on our e-shop:

At the same time, we decided to stop accepting new orders for Original Prusa i3 MK2S kit and assembled printer as the number of orders got quite low. But don’t worry, we have all replacements in stock to provide long-term support to all current users of this printer.

Useful links:

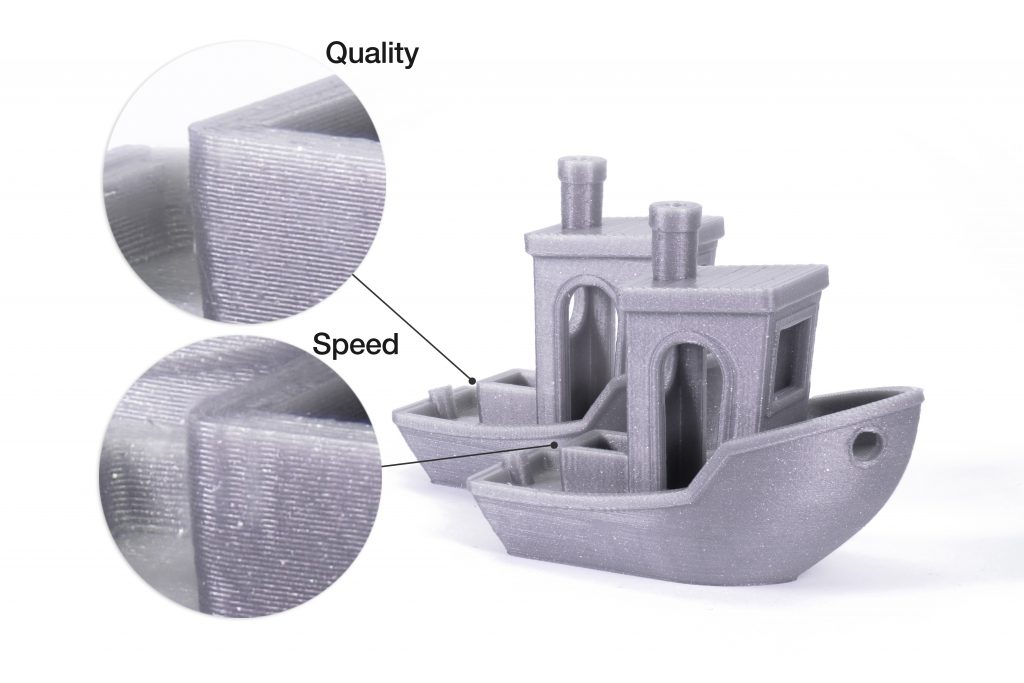

New print profiles were just published for MK3 and MK3S. To get them, use Slic3r PE 1.41.3 or newer, which you can find in our updated drivers. We added the 70μm profile as a great option sitting between the 50μm and 100μm profiles. It is a great alternative for miniatures printing. 150μm Optimal and 200μm profiles were both split into Quality and Speed versions. Quality slows things down a bit and gives you better surface quality, while Speed speeds things up without much sacrifice to the settings we provided before. If you had inherited profiles modifying the system ones, you are not losing those, but I suggest to try the new ones. Slic3r PE has a lot of news by itself, but more on that in a separate chapter.

Original Prusa MMU2S for MK3S/MK2.5S

While the MK3 results in the survey were literally amazing, customer’s feedback to MMU2 wasn’t what we imagined. Although many of you print with five filaments without any hassle, there are users facing several issues with multi-material printing – usually related to reloading the filament and secondly from the filament getting tangled as the MMU2 is unloading filament from the five spools.

Before I even start about MMU2S, I have to tell you, that every current owner of MMU2 will be getting the upgrade to the MMU2S (self-printed parts for the extruder upgrade) for free no matter where in the world you are. If you want to receive factory-printed plastic parts for the new extruder with the upgrade, you can get them for 20 USD extra.

Everyone will receive a voucher for MMU2S upgrade with free shipping by the end of this week and all already placed orders will be automatically switched to MMU2S. No need to contact support, we will process all of these through our system. With such a cutting edge product, it is very important for us that everyone is happy.

When we were redesigning the MK3S extruder, MMU2 reloading problems were one of the things we thought of and we wanted to solve them. With the MMU2S we managed to sense not only that the filament is present, but that it actually reached the Bondtech gears. You have to switch a few parts on the MK3S extruder (which is a part of the MMU2S upgrade). But with this mod, the filament sensor detects when the idler doors open a bit as the filament pushes Bondtechs apart. We have done an incredible amount of testing, as you can see in the photos below, and I’m sure that the reliability of the unit has increased significantly.

The testing process of the MMU2S took 2 months to finish, we used 20 printers and we printed 478 test blocks designed to test frequent switching of all five filaments. There were two types of blocks: the first one took 19 hours to print, it has 607 filament changes and the second one took around 70 hours to print, while it had 3520 filament changes, so the total value of filament changes was nearly 600.000. Both blocks were designed to test frequent filament changes (even in higher layers). More than 93 % of this prints were successfully completed (about 19 % of prints required user attention, but they did not fail) and we are still working on the firmware improvements to decrease the number of failed prints even more.

We printed two types of blocks – one took about 19 hours to print (607 filament changes), the other around 70 hours (3520 filament changes)

The tangling of the filament while unloading was a tougher nut to crack but we solved it by having a separate buffer which contains the unloaded filament. The user survey showed that the previous existing spool holders work properly if the filament guides are removed and the spools are placed far enough from the printer. Unfortunately, it took a lot of space.

In the new revision of MMU2S handbook, you will find tips, how to arrange everything for successful print and how to save some space.

To summarize everything, with MMU2S you will get the new MK3S/MK2.5S extruder parts (with new filament sensor) and the new filament buffer. The MMU2 unit is remaining the same as most of the problems were elsewhere. And yes, if it isn’t clear from the previous lines: when you have an MK3 or MK2.5 and order the MMU2S, you are getting the MK3S/MK2.5S upgrade along with it as well! In other words – MMU2S is MMU2 + MK3S/MK2.5S upgrade + filament buffer.

We are still waiting for some parts, but we will be able to start shipping the MMU2S over the course of next week. And once more – ALL MMU2 users will get vouchers for this upgrade FOR FREE by the end of this week.

New firmware builds – 3.5.3 and 3.5.2

The new firmware is also being released with support for MK3S / MK2.5S (version 3.5.3) but brings many improvements for MK3 and MK2.5 (3.5.2), too. One of the standouts is a different method for controlling the heatbed power which reduces the PSU clicking noise. Finer mesh bed leveling is in the works by popular community demand but it just takes time to do properly without hitting the magnets which throw off the readings even thru the steel sheet. We also strongly suggest babysitting any printer with any untested community firmware as safety checks might not work properly.

Textured sheets

The difficulty of their manufacturing is legendary, maybe on the level of unobtainium. We actually shipped over 10 000 of those so we have achieved some success here. But even a year after we introduced them to the public, we learn over and over again how hard they are to make. As our only acceptable option for us is a 0% area removed in the cross-cut adhesion test, and this is a challenge for every manufacturer. But we can’t lower our standards just to get them out as we know that this spec can survive PETG and even flexible filament prints removal. You can find some clones even, which is embarrassing with a product we developed, but none of them are up to our standards.

We ended up building our own testing lab, where we can inspect every part of the process: from making the powder (Ultem/PEI can break even the best Japanese cryo grinders) to the powder coating and baking in a custom in-house-made furnace.

You could see it evolving with slightly modified designs going out. Thanks to our research of the coating process, even the “regular” PEI sticker sheets now come in black. They are specially treated to prevent rust. Regularly shipping to 160 countries provides us with a lot of interesting challenges. But thanks to our improvements, the sheets won’t rust even under extreme humidity conditions like the ones found on seaside locations. Each technology iteration is now tested in a humidity chamber with salt mist. A huge departure from the beginnings in the basement 😀

Long story short, we now have suppliers able to manufacture it up to our standard and right now we are testing the repeatability before we start big batches. I do not want to promise any dates, burnt myself too many times and made a lot of people sad, but I am excited that we will be able to provide the best print surface experience to everyone “soon” 🙂

Original Prusa SL1

With our first resin-based 3D printer we don’t want to leave anything to chance. We finished the second internal beta testing of SL1 last week with really awesome results. We have managed to solve all hardware issues and all promised features are working great now. The next step is an external beta-test starting in late-February with more than 50 SL1 printers (testers have already been selected).

Also, we have switched some parts for different ones to get better printing results and construction strength. Unfortunately, we had to sacrifice some more time because of these improvements as some of our suppliers have been delayed by the Chinese New Year.

First units should reach the first customers in late March and we have already extended the special pre-order price of the printer and bundles until then. With this extra time, we will be able to deliver you the best possible product we can.

Anyway, the biggest issue which occurred during the internal testing process was a painful one: printing displays often cracked on several units during printing of large models (80-100 % of printing area). This problem can be very common on cheap SLA printers, but we have solved it by changing most parts of the display mount. And remember the tilting mechanism of our SL1? Now it can calculate the size of the printed layer and it adjusts the tilting speed to further decrease the stress on the screen. Also, there was another problem – with the precision on the Z axis. We changed the supplier of rods and added a second spring to the Z-axis motor. Z-axis precision is now guaranteed and print quality is fantastic.

With these hardware problems solved, we are now focusing on the improvement of the calibration process, automatic supports in Slic3r PE and overall user experience.

As you may know, SL1 will support various resins from different manufacturers. We have already tested over 100 types of resins made by 3DM, Bluecast, Jamg He, Monocure 3D and many more. All of them will get their own profiles in Slic3r PE and we are still testing more resins to offer you a huge range of materials, so you will just select the brand you are using and Slic3r will do the rest. Since we’re developing an open-source printer, it means you can use pretty much any 405nm resin. Plus, the bottom of the tank is easily replaceable – so you don’t have to buy any expensive cartridges or complete tanks.

Slic3r PE

If you are following us closer you have probably noticed that Slic3r PE development is gaining some serious speed. If you haven’t, make sure to check out our GitHub. I mean, if you are feeling adventurous and want to give some early versions a shot, you can test the new GUI and actually help us shaping the look of our slicer. Slic3r PE team is now 7 people strong and listening. Our goal is to have the best slicer out there for every printer, not just the Original Prusas. It works great, receives regular bugfixes and new features, it is improved based on user feedback and it’s free. I am very proud as of right now, even getting bugs fixed in a timely matter isn’t standard if you know what I mean 🙂

Prusament

I will be repeating myself again, but we did not expect such a demand. But … Again we are desperately sold out and received universal praise. When we made it available on US Amazon it instantly sold out and back ordered so much, Amazon decided to make it unavailable. We are continuously increasing the production capacity of our lines and our goal is to achieve a non-stop production with fully robotic operators. Besides that, I immediately ordered two more lines to our five which are coming soon, but I realized it won’t be enough and ordered 6 more a few days ago. It’s not a stock item (wait time is 6 months) and when they come we have to do all our mods to achieve the quality we want but I hope we will be able to meet the demand this year. I still have a feeling I will need to order more though. 😀

More to come!

I hope this update covered everything you wanted to know about the current developments at Prusa Research. There’s a lot going on right now (as always) and we still have some cool stuff to announce later on. But first things first – we hear your feedback, so I hope you will be happy with the updated MK3S and MMU2S, and that you’ll like the improved reliability and new features.

Remember to keep checking Prusaprinters.org for latest updates from Prusa Research and many other interesting guides and tutorials. And, of course, feel free to leave your comments if you have any questions.

Happy printing!

Can’t wait to upgrade my MK 3…also my MMU 2…

Will be uploading new firmware today!!!

I will be convincing my school district to buy MK3S & MMU2S for our new MakerSpace!!!!

Also will be strongly suggesting the SL1

When you succeed, we succeed so I wish you much success!!!

Please tell me about your experience with the mmu2s. I tried to print an octane car from the game rocket league with watersoluble pva as support, but it failed several times.

This is cooler than Apple Keynote, really nice this free update!

I can only agree with that! Much better than everything else on the 3D printer market.

All good, I just don’t see the “S” in MK3s :/

10 points for Prusa!!!! You guys are always improving and are really open to customer feedback. Keep it up and thank you!

All sounds good to me except I’m sad that the survey didn’t show high demand for a larger print area as I was hoping for the next model to have 300mm x 300mmm x 300mmm or a little larger! 🙁

+1

I was also hoping for a 500x500mm print are…

I m also very interested in a printer with a bigger bedsize!

Even one axis being longer would help me. If Y got up around 300mm that would be amazing.

When will the new firmware be ready for MacOS?

2.2.3 Drivers for Mac OS are on the website as of today. https://www.prusa3d.com/drivers/

I just use Slic3r on Mac OS to update firmware, works fine for me

I’m happy with my mk3, consistently prints great, love the removable print bed, smooth pei is great. I’m surprised that the survey didn’t show more on wanting a bigger build volume. I dont personally have any need for the mmu. I just want a bigger print volume on a prusa not some other brand. Would love to be able to print a helmet in one piece instead of pieces. Something like 300×300×300 or larger. I would totally order a mk3s-XL if you made one. I hope the next news on the FDM front is about a larger print volume. A happy mk3 owner.

Yay Josef! & the whole team of course.

Getting tired of the whole “We never anticipated this sort of demand or growth” excuse. You have a Ferrari so I think its about time that you have products to actually ship to customers instead of having people wait months. I’ve been checking the site for the MK2s to MK2.5 for months and it still has a 1 month lead time.

We’re growing as fast as we can! Hiring more people, renting second warehouse, spreading to more buildings… We’re the fastest growing tech company in Europe (according to Deloitte) but still, it’s hard to keep up with the demand.

I wouldn’t expect us to have thousands of units in stock anytime soon if ever. We like to constantly improve our products, so having 10000 in stock would mean 10000 that won’t get the latest improvement that we just implemented.

Consider simply placing the order and waiting the month. If you want to, you can choose to pay via invoice (we’ll let you know when it’s ready to ship and time to pay).

If you’ve been looking for months, you could have had it in your house at one month fewer than that amount of months,

I’m not sure why you feel the need to wait until the lead time is shorter.

+1 mark

I have been waiting for 6 months: o

outrageous, I’m fed up.

I was going to cancel my order and I see that it has just been shipped, damn I even want more: /

Instead of doing novelties like pram, or sl1, you’d better finish what you started and catch up.

Nice words but you think that money …

(Google Translate)

As a new user with a Mk3 less than a week old, it’s going to be upgraded already! Well done, terrific service and a great attitude.

I just ordered the MK2 >MK2.5 upgrade a few days ago, will it ship as MK2.5S?

Thanks for sharing this information.

I am really happy to hear of the improvements to the MMU2. The issues the improvements are aimed at are indeed the issues that have kept me from truly enjoying my printer as i did before the upgrade. Absolute kudos for the way you are handling it and i hope i can start reliably print multicolor objects soon. Really looking forward to it.

Good surprise! I received mine today which is an mk3s indeed!

The new extruder means that there is no filament flow detection anymore on this printer, right ?

Am I wrong or this is a stepback?

I mean: ok it will detect filament presence, but it won’t detect if the filament is actually moving. So if it’s jammed it won’t stop the print.

You guys are awesome!

Since the moment I started to use the MK3, I have more and more abandoned my other two printers. Using Prusa machines is like working together with a very experienced team to achieve the best possible results!

Also, your updates always get me freaking excited and I love your philosophy and customer support. Such a good company! Please keep it up!

Awesome customer service! 10 Points for your whole team! Many thanks for the continuous improvements a s making the upgrades free for recent buyers.

I had my MK3 with MMU2 for a while. Seeing this is nice. I need a change in the MMU2 since it was quite unreliable! Will get it soon!

Hello,

What happens to the orders for the MK3 (fully assembled printer) which have been ordered recently and have not been shipped yet? Will the MK3S be shipped directly here?

Yeah all orders are automatically upgraded from MK3 to MK3S 😉

Please make a larger printer, I like Prusa and I really don’t want to buy from other brands.

I ordered a MK3 and the MMU2 at the end of last year, which are planned to be delivered around middle and end of march as far as I know (so only some more weeks to go).

Do I automatically get my order upgraded to the MK3S with the MMU2S now, or at least vouchers to get the upgrades for free?

Yes, all orders were upgraded to the latest models for free 🙂

This release was missing info about the printed parts not coming in the Mk3 to Mk3s upgrade kit. When I went to check you included filament to print it yourself. Shouldn’t there have been two options. One with printed parts and one without?

Just excellent. Upgrade path is totally appreciated.

Real hopeful for the mmu2s, since mine has basically had unending switching problems on my 2.5. It’s been a bit disheartening, but i’ve held out hope for a quick update.

If we have the MMU2 and a MK3, are the MK3s parts included in the free upgrade for the MMU2S?

Yes they are 🙂

Well done!

This is great and all, but yet again the MK2/S is missing out on the latest firmware. It’s been over a year since owners of these printers have had an update, and this isn’t really acceptable for a printer you still sell.

I almost got mad until I read that recent MK3 buyers will get the upgrade for free, because mine was shipped on the 12th of February and I read this two days later! It’s my first Prusa and I want to thank you already now for being a good company. 🙂

This is a very nice update and i have already ordered it for my Mk3. Thanks for all the good stuff and keep innovating!

Is there any chance you could add dates to your articles? When you say thing like “Everyone will receive a voucher for MMU2S upgrade with free shipping by the end of this week” there’s no way to tell which week!

Excellent overview / update of your fantastic work !

Hi,

Maybe a better spot for this comment would be on Github, but it would be super nice if the G-code was exported like it is for other cnc machines, with “N” line numbers and a carriage return/end of block (;) after each command. The text is near impossible to read exported as a large lump of a paragraph and difficult to add in custom G-code lines. Not sure if anyone else has this concern…

There are new lines after each command, try different text editor 😉

This is a step back into the rite direction, thank you Prusa for hopefully fixing a flawed component on a great machine.

Really looking forward to finer mesh bed leveling when it’s ready!

And the Mk3S Upgrade sounds great, easier servicing on the extruder is a blessing and a more reliable sensor sounds quite good too. I’m just wondering if the new sensor can still sense the filament motion (to possibly detect jams like it was initially advertised for the old sensor) or if it will only detect filament presence like the sensors on any cheap machine.

hello, is there anyone in Portland, OR who would be willing to help setup our PRUSA to MMU2? we have all the parts but cannot get it to work for life of us.

does this update do away with the need to calibrate the bowden tube length o n the mmu2?

Yes 🙂

Will the MMU2S work on the MK2S.

No. It will, however, work with the MK2.5S upgrade, MK2S is missing the filament sensor and Bondtech gears necessary for the MMU2S to work

A very interesting and informative update. Thanks you Josef.

So, I’m wating for 4 months now for the “free upgrade”.

Whats wrong with you?

Wow, I didn’t get any voucher for my MMU2 upgrade. So how do I upgrade?

A great blog!